We invite you to read our newest blog article with Gediminas Raciukaitis who is president of the Lithuanian Laser Association and learn more about the laser industry.

First laser technology in Lithuania

Not a lot of people know that Lithuania had laser technology since 1966– longer than most other countries in the world. Lithuania’s laser industry can be traced back to three students who were all sent to Moscow in 1962 to study quantum electronics– and, with it, the emerging field of laser technology. They helped fire the first laser in Lithuania in 1966 and went on to found the Laser Research Center at Vilnius University and the Center for Physical Sciences and Technology – which is where I am now head of the Department of Laser Technologies. Anyone in Lithuania with anything to do with lasers has some sort of connection to at least one of these bodies, and usually to both of them. They’re only 20 kilometers apart. Commercial lasers for science have been built in Lithuania since 1983.

Laser Industry in 2022

Now in Lithuania, there are more than 50 companies manufacturing lasers or optical components for lasers. Together, they employ around 1,400 people and generate annual revenues in the region of 176 million euros.

For someone, it could seem like not a lot, but No, it’s not. But Gediminas Raciukaitis says: ”If you have a mobile phone, you can be pretty sure it contains a part that was made by Lithuanian USP lasers. For certain high-tech systems, our small country can hold its own with the U.S., China or Germany.”

Market breakthrough

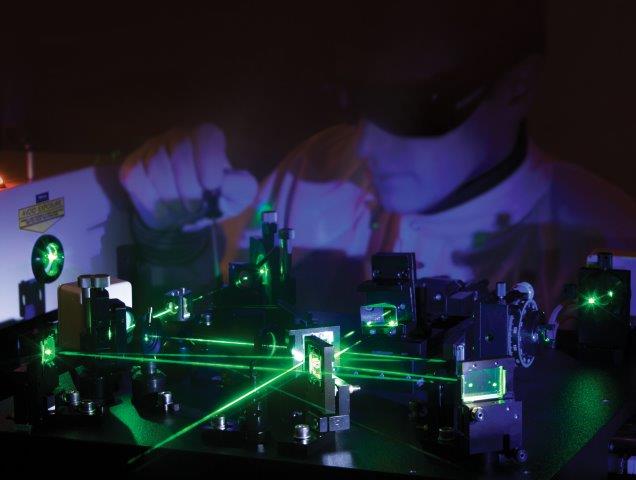

Lithuania has always been a strong player in the field of scientific lasers. Right now, country is working on some of the most intense lasers in the world, as part of the Extreme Light Infrastructure (ELI) project, a European research initiative.

It’s around 15 years since the first Lithuanian companies began producing lasers and optical components expressly for the industry. Real market breakthrough was the commercialization of the USP laser. These days, we’ve a whole spectrum of manufacturers producing lasers and laser-processing machines, or optical components such as coated lenses, or optical para- metric oscillators.

OPOs are used to convert and amplify laser light. Ninety percent of all OPOs sold worldwide are made in Lithuania. There are also a number of contract manufacturers operating here– companies with laser machinery who provide high-end laser-processing services such as glass cleavage. Right now, several companies are moving into medical engineering.

Lithuania’s Flagship Product

Gediminas Raciukaitis says that if he had to choose an area, then it would be OPCPA, a technology that is used to amplify ultrashort laser pulses. Lithuanian companies have played a strong role in this field for a long time. In general, when it comes to USP lasers and their components, the country is competing on even terms with the rest of the world. For me, that’s great to see, because these are all cutting-edge technologies that will enable us to build lasers of ever-greater intensity.

Secret behind Lithuania’s success in laser technology

That sometimes it’s good to be small. It means that we all know each other personally. Most companies are spin-offs from the leading institutes, and most of the company founders and workforce are of the same age as the people from the other companies and the institutes and know each other because they all studied together. It’s very common to move from academia to industry and back again. As a result, research and development at the institutes are strongly geared toward what companies actually require. In the laser community, we all trust each other – even across company boundaries. Sure, we’re still market rivals, but companies here tend to work together rather than against one.

Article is based on the interview at Trumpf – Laser Community Magazine.